Custom Carburetor Tuning and Rebuilds

JD’s Auto Restoration Center is a full service high performance carburetor tuning, and rebuilding. Established since 1996, we perform high performance carburetor tuning, and rebuilding on any make or model vehicle.

We offer a complete restoration and tuning service for your carburetor. We can restore your existing carb to show quality condition. This specialty service transforms tired, worn-out O.E.M. muscle carbs back to their original condition. And because this is a “custom” service, each order is personally followed through from start to finish by one of our qualified technicians.

We do a full inspection of carbs for metal fatigue, slightly-stripped threads, hair-line cracks and worn-out throttle lever bushings.

Testing of sub assemblies-chokes, vacuum secondary’s, float bowls, metering blocks-to verify performance before final assembly takes place.

Replacement of gaskets, diaphragms, power valves and needle/seat assemblies.

Flow-stand testing of all carburetors to confirm correct metering of air/fuel volumes.

We have technicians with over 30 years’ experience to provide quality service and repair work. Our technicians are AC Delco, Ford, and GM certified. We operate a fully computerized shop with the latest equipment for today’s high tech problems. Our mechanics are skilled technicians who maintain their skills with specialized hands on training for solving the problems today’s vehicles face. This helps you save money by taking the guess work out of repairs.

We handle high performance carburetor tuning, and rebuilding for the everyday driver to the race enthusiast. We have a long list of best-in-show cars as well as First place winners. We handle any make, model or year. Our shop rates are competitive. We also provide high quality service and routine maintenance on your classic automobile.

Antique, Classic or Muscle Car? We cater to the Antique, Classic or Muscle car enthusiast. Our experienced technicians can perform service, repair, custom restoration work and performance upgrades.

Holley Carburetors

Holley has been the undisputed leader in fuel systems for over 100 years. Holley carburetors have powered every NASCAR® Sprint® Cup team and nearly every NHRA® Pro–Stock champion for four decades. Now, Holley EFI is dominating the performance world as well as our products for GM’s LS engine. Holley’s products also include performance fuel pumps, intake manifolds & engine dress–up products for street performance, race and marine applications. As a single solution, or partnered with products from other Holley companies – Hooker Headers, Flowtech Headers, NOS Nitrous, Weiand, Earl’s Performance Plumbing, or Diablosport – Holley products can give you the edge you need over the competition.

A Brief History in Carburetors

The carburetor was invented by an Italian, Luigi De Cristoforis, in 1876. A carburetor was developed by Enrico Bernardi at the University of Padua in 1882, for his Motrice Pia, the first petrol combustion engine (one cylinder, 121.6 cc) prototyped on 5 August 1882.

A carburetor was among the early patents by Karl Benz as he developed internal combustion engines and their components.

Early carburetors were the surface carburetor type, in which air is charged with fuel by being passed over the surface of gasoline.

In 1885, Wilhelm Maybach and Gottlieb Daimler developed a float carburetor for their engine based on the atomizer nozzle. The Daimler-Maybach carburetor was copied extensively, leading to patent lawsuits, but British courts rejected the Daimler company’s claim of priority in favor of Edward Butler’s 1884 spray carburetor used on his Petrol Cycle.

Hungarian engineers János Csonka and Donát Bánki patented a carburetor for a stationary engine in 1893.

Frederick William Lanchester of Birmingham, England, experimented with the wick carburetor in cars. In 1896, Frederick and his brother built the first gasoline-driven car in England: a single cylinder 5 hp (3.7 kW) internal combustion engine with chain drive. Unhappy with the performance and power, they re-built the engine the next year into a two-cylinder horizontally opposed version using his new wick carburetor design.

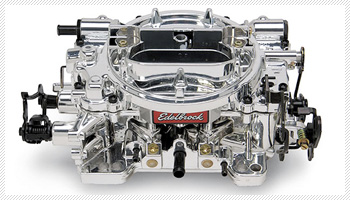

Edelbrock Carburetors

Every Edelbrock Carburetor is manufactured in the USA and has been specifically designed and tuned by Edelbrock engineers to provide the widest overall torque range. For unmatched street performance, combine them with Edelbrock Performer, Performer Air-Gap, Performer EPS, Performer RPM, RPM Air-Gap or Torker II manifold and camshaft combinations, as well as most stock and other aftermarket manifolds of similar design.

Carburetors were the usual method of fuel delivery for most US-made gasoline-fueled engines up until the late 1980s, when fuel injection became the preferred method. This change was dictated more by the requirements of catalytic converters than by any inherent inefficiency of carburation; a catalytic converter requires much more precise control over the fuel / air mixture, to closely control the amount of oxygen in the exhaust gases. In the U.S. market, the last carbureted cars were:

- 1990 (General public) : Oldsmobile Custom Cruiser, Buick Estate Wagon, Cadillac Brougham, Honda Prelude (Base Model), Subaru Justy

- 1991 (Police) : Ford Crown Victoria Police Interceptor with the 5.8 L (351 cu in) V8 engine.

- 1991 (SUV) : Jeep Grand Wagoneer with the AMC 360 cu in (5.9 L) V8 engine.

- 1993 Mazda B2200 (Light Truck)

- 1994 (Light truck) : Isuzu

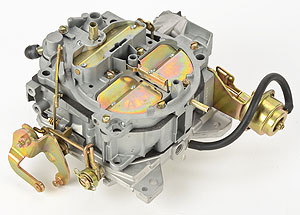

Carter Carburetors

Brothers or identical twins?

Many people mistake the AVS for an AFB. While the two models are very similar, the AVS, introduced in 1966, uses a spring-loaded, rather than counter-weighted, secondary air valve.

In Australia, some cars continued to use carburetors well into the 1990s; these included the Honda Civic (1993), the Ford Laser (1994), the Mazda 323 and Mitsubishi Magna sedans (1996), the Daihatsu Charade (1997), and the Suzuki Swift (1999). Low-cost commercial vans and 4WDs in Australia continued with carburetors even into the 2000s, the last being the Mitsubishi Express van in 2003. Elsewhere, certain Lada cars used carburetors until 2006. Many motorcycles still use carburetors for simplicity’s sake, since a carburetor does not require an electrical system to function. Carburetors are also still found in small engines and in older or specialized automobiles, such as those designed for stock car racing, though NASCAR’s 2011 Sprint Cup season was the last one with carbureted engines; electronic fuel injection was used beginning with the 2012 race season in Cup.

In Europe, carburetor-engined cars were being gradually phased out by the end of the 1980s in favor of fuel injection, which was already the established type of engine on more expensive vehicles including luxury and sports models. EEC legislation required all vehicles sold and produced in member countries to have a catalytic converter after December 1992; among the last carburetor-engined models produced in these countries were most of the Ford Fiesta MK2 range (1989) as well as cheaper versions of the Nissan Primera (1990) and Peugeot’s 106 and 405 range – the French built 106 went into production just over a year before carburetor engines were outlawed in the EEC.

Quadrajet Carburetors

A major change to the Quadrajet was implemented for the 1975 model year. These newer carburetors are considered “Modified Quadrajets” or “Mod Quads”. In addition to the casting revisions that result in a physically larger carburetor, the primary metering rod length is different from ’74 and older Q-Jets. They were also equipped with a self-contained choke mechanism that no longer relied on an intake manifold mounted choke, and a number “1” was added to the beginning of their identification numbers.

Quadrajet carburetors were also built under contract by Carter. This seems to have happened at times when Rochester’s facility could not keep up with demand. Carter-built Quadrajets will have the name “Carter” cast into them, but are functionally identical to the Rochester-built equivalent. The “newest” Q-Jets were built for, and sold by Edelbrock. There were several versions made, for both stock replacement and “performance” applications. One version was specifically intended as a replacement for Carter Thermoquad carburetors. The Edelbrock Q-Jets have been discontinued, although at this time Edelbrock still supplies some replacement parts.

A high performance 4-barrel carburetor

Under all engine operating conditions, the carburetor must:

- Measure the airflow of the engine

- Deliver the correct amount of fuel to keep the fuel/air mixture in the proper range (adjusting for factors such as temperature)

- Mix the two finely and evenly

This job would be simple if air and gasoline (petrol) were ideal fluids; in practice, however, their deviations from ideal behavior due to viscosity, fluid drag, inertia, etc. require a great deal of complexity to compensate for exceptionally high or low engine speeds. A carburetor must provide the proper fuel/air mixture across a wide range of ambient temperatures, atmospheric pressures, engine speeds and loads, and centrifugal forces:

- Cold start

- Hot start

- Idling or slow-running

- Acceleration

- High speed / high power at full throttle

- Cruising at part throttle (light load)

In addition, modern carburetors are required to do this while maintaining low rates of exhaust emissions.

To function correctly under all these conditions, most carburetors contain a complex set of mechanisms to support several different operating modes, called circuits.

Contact us today in Huntingdon Valley, Pennsylvania, and let us handle your automotive restorations. Some of the Auto Body Repair, Restpration, High Performance and Dyno Tuning Service Areas we serve: